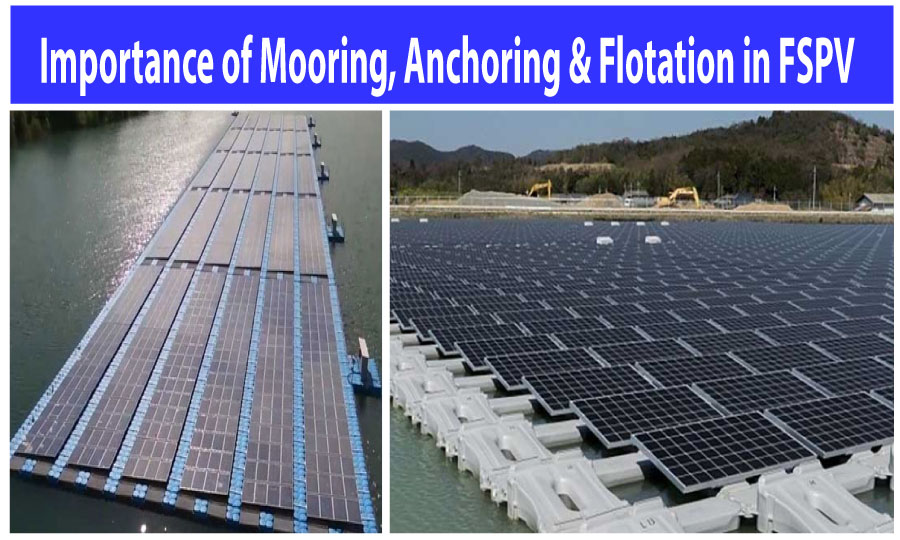

Importance of Mooring and Flotation system in a Floating Solar Project

Each FSPV reservoir/site has a unique set of challenges, thus proper planning & designing of mooring and flotation system in a project is of great importance to withstand the uncalled for adversity during the project lifecycle…

The global FSPV industry has grown at a rapid rate and governments and private developers around the world have set ambitious targets towards increasing the share of renewable energy in their power generation portfolio.

Since FSPV is a fairly new industry that utilizes new technology (and expertise) related to floatation systems, mooring, and anchoring, etc., such kind of expertise is not readily available in the global market.

The mooring and floatation system needs to be designed to withstand worse storms and weather conditions for at least 25 years.

Overcoming Challenges

Based on Inventocean Technologies’ experience, each FSPV reservoir/site has a unique set of challenges. Mooring and Anchoring are very site-specific.

In some reservoirs the anchors cannot be placed on the seabed, others have largely uneven seabed profiles with unreliable Bathymetric surveys.

Mooring and anchoring becomes challenging in dams where there is a large water level variation. Similarly, FSPVs on rivers can experience very high drag loads due to currents.

Multiple mooring lines with pre-determined lengths and engineered mooring design are essential to ensure balanced load sharing. Varying mooring line lengths result in varying line stiffness’s and therefore uneven load distribution.

Mechanisms and Engineering Design should be able to accommodate all these challenges. No specific Indian codes and standards are available for Floating solar mooring design.

The FSPV mooring design should sustain up to 200km/hr wind speeds in coastal areas. The off the shelf mooring lines cannot sustain 25 years of design life and therefore more superior fiber lines are needed for longer design life.

Apart from engineering design, the Installation of FSPVs in the marine environment is a challenge of its own. Specialized inland barges and trained marine crew is required to install these systems within tight tolerances as per the engineering design.

In our experience costs related to mooring & anchoring engineering and installation may vary significantly based on the site conditions. Developers should do an accurate assessment of site conditions and plan suitable mooring and anchoring systems before bidding for jobs.

Thorough engineering and planning are essential and must for successful FSPV projects across India.

Column Contribution by:

Rahul Kanotra (Subject Matter Expert – Naval Architecture)

Founder & Director – Inventocean Technologies Pvt. Ltd.