Importance of choosing quality solar cables

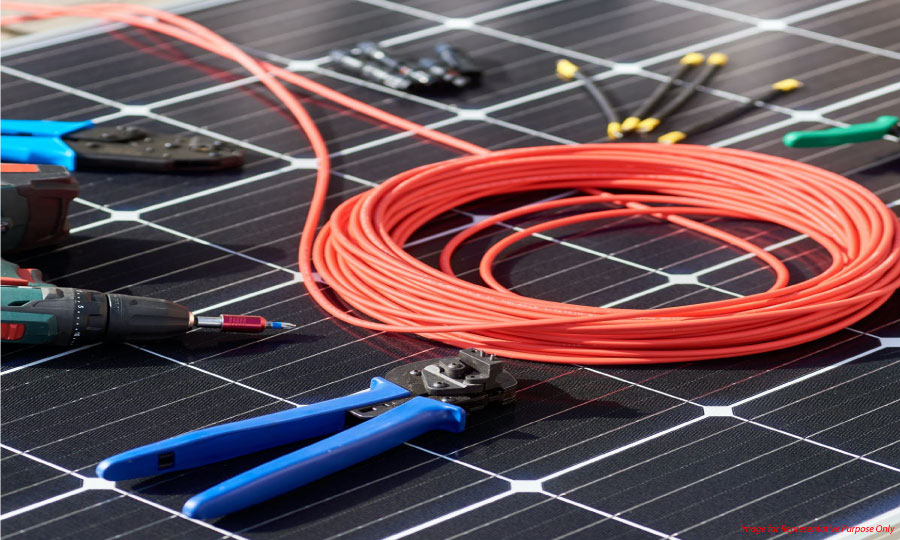

The use of quality solar cables with proper installation is of utmost importance as the money saved by using low-quality cables is not much, but the adverse effect on the project performance is immense.

Wherever there is electricity, wire and cable must be present. These wires and cables play an important role in getting optimum performance from any electrical system.

Electrical cables come in a variety of shapes and sizes, to suit the need of variability of purposes. So it is important that they must be adapted to the intended use. One such cable type that is gaining traction in the market is solar cable.

Thus, in a solar power system – the need for quality solar wire and cable with proper installation becomes of utmost importance. This is because in a solar power project, these wires & cables are mostly laid outside and are exposed to high temperature and harsh weather conditions during the long lifespan of around 20 to 25 years of a solar power project.

What are Solar Cables?

Solar cables are cables that are specifically designed to safely transfer DC solar energy across a photovoltaic system. These solar cables are designed to have high mechanical strength in order to endure the PV system’s harsh requirements as well as severe weather conditions.

Though, both DC and AC cables are essential parts of a solar PV system, they are used in solar power plants to generate solar energy for homes, businesses, and industries. Only when the cables used in solar power plants for producing solar energy for residential, industrial, commercial rooftop, or ground-mounted are of sufficient size and quality, a solar PV system can have a 25-year life expectancy.

Types of Solar Cables

In a solar power project, different types of solar cables are required to produce solar energy. Both DC and AC cables are used in a solar power plant. PV panels and inverters (including junction boxes) are connected via direct current (DC) cable, whereas the inverter and the sub-stations are connected via alternate current (AC) cable.

Furthermore, different voltage levels ranging from low to extra high are used in a standard solar PV project, depending on the requirements. While low-voltage power cables are used to connect the panel to the combiner box, the combiner box to the inverter, and the inverter to the transformer. On the other hand, medium-voltage power cables are used to connect the transformer to the substation, whereas high voltage and extra-high voltage power cables are used to connect the substation to the grid.

Solar Cables Importance in PV Project

Solar cables are used in a solar power plant are specifically designed to safely transfer DC solar energy from one part of a photovoltaic device to another. Proper cable management is one of the most important aspects of the safety and longevity of every photovoltaic (PV) system.

Since cable installations in any solar projects being subjected to direct sun radiations while bearing extreme temperatures as well as air humidity. Thus, solar cables are designed to have high mechanical strength that can withstand the PV system’s harsh requirements both indoors and outdoors, as well as severe weather conditions.

These solar cables not only have to be sturdy but should also be weather-resistant. They are also subjected to withstand mechanical stress from pressure, bending, or stretching that are being experienced during installations. In addition, solar cables are also exposed to chemical stress in the form of acids, alkaline solutions, and saltwater.

Since regular cables are unable to handle these harsh conditions as well as the overheating effects of a solar panel, solar cables are designed to avoid problems such as overheating, low reliability, durability, and power loss problems. Thus, these cables are the main connecting elements that help the PV system to function properly.

Current Market Scenario

India has witnessed a surge in solar power generation over the recent years backed by government support and initiatives thereby creating demand for solar power technologies and electrical products. As a result, the domestic solar power market has also seen a boost in demand for Solar Wires & Cables – a special kind of wires and cables suitable for solar energy.

On the other hand, due to cutthroat competition in the market, the solar power sector has witnessed an unprecedented fall in tariffs – making it one of the cheapest energy sources. However, this has also led to severe cost-cutting measures by developers and installers – so as to maximize profits.

It has been observed that some installers use very low-quality cables to minimize installation costs and improve their profit margins. While some of them fail to properly size the cables, too. Although the money saved by incorrect cable sizing and using low-quality cables is small, the adverse impact on the Solar PV system is significant.

Ramesh Singh – Vindhya Telelinks Limited points out in this regard – “To reduce the installation cost and increase their profit margin, some installers use poor quality cable and/or undersize them. The result of using such poor quality/undersize cables can lead to very serious performance issues of the Solar Power plant as these cables will have much higher energy loss, overheating, reduced life due to premature failure of polymers, the possibility of short-circuiting, fire accidents.”

Since a life cycle of a solar project is 20-25 years- it becomes important that quality cables of proper size are opted for by the installers – to get optimum performance from the solar PV system.

Quality Solar Cables – Lifeline of a Solar Project

To ensure a reliable electricity supply with minimum loss in energy generation – it becomes important that high-quality solar cables, as well as other electrical components, are opted for in the project to get optimum performance during the lifecycle of 20-25 years of the solar project.

V K Bajaj, COO – Apar Industries said, “After investing huge amount in Solar Panels and other high-quality components, if poor quality cables are used, it will be a long term loss and revenue loss in case of Power generated but not utilized. Cables are the lifeline of any Solar Project and cables must be sourced from Reliable Cable manufacturers.”

The outer insulation cover can break if poor-quality cables are used in a solar power plant to generate solar energy for a rooftop or ground-mounted installation. This is sure to lead to degradation of the system’s performance and results in plant inefficiency.

Talking about the adverse effects on the system Nitesh Vaghasiya (Chairman & Managing Director) Ultracab pointed out, “The adverse effect of using low-quality solar cables are many – like an increase in transmission losses, a decrease in efficiency of power generation and durability, as well as breakdown may occur of Solar Power Plant after some period and make a huge loss of the whole system.”

Though in terms of value, solar cable accounts for a very minimal cost in a solar PV project. But, it should be remembered that the stakes are high.

Naman Singhal- Director, PRIME CAB says – Adverse effects can be numerous when the solar cable quality is compromised in a project in order to save the cost. Some of them can be as huge as the failure of the whole project as these solar cables play a very integral part in connecting all the electrical components of the project. And some other effects can be the non-efficiency of the solar plant in producing and storing the energy due to the incapability of bad quality solar cables.

From not getting the right cables to not configuring the cables right, even the smallest of errors can lead to inefficiency, loss of power and can lead to certain safety hazards as well.

While commenting on having quality solar cables for the project, Naman Singhal- Director, PRIME CAB said, “Solar cables quality is the most important thing in defining the performance and efficiency of the whole project. Moreover these solar cable networks are generally laid outdoors over the ground, and thus are exposed to some harsh conditions like extreme temperatures, humidity, rains and other weather conditions. And a quality solar cable becomes very important in this respect to keep the whole system running.”

“A typical solar project should last at least 25 years for it to give good returns in terms of its value and this can only happen with the help of quality solar cable only. So the solar cable quality should be a prime concern for the contractor responsible for its works, and in my view, that is one thing that should not be compromised,” he added further.

Selecting Quality Solar Cables for PV Project

Cable companies have put a lot of effort into making solar cables suitable for the most demanding applications. Efforts have been put in to produce solar cables with the highest resistance to the atmospheric challenges, such as UV, ozone, and humidity. In addition, it is also important to make them suitable to withstand severe temperatures (-40°C to 120°C), the harshest weather conditions along with having high resistance to abrasion, impact, tear, and pressure.

Pointing out the key quality aspect of the solar cables, Ramesh Singh of Vindhya Telelinks commented, “Since solar wires and cable have to be installed outdoors and are subjected to extremely harsh operating conditions. This demands that these cables must be designed to have –

- Good weather resistance, Ozone Resistance, UV Resistance

- Withstand wide temperature range, typically -40oC to 120 oC

- Withstand mechanical stress such as compression, tension, bending and shear loads

- Abrasion resistance

- Acid and base proof

- Should have high dielectric strength

- Should be Flame retardant and halogen free

- Should have small diameter

- Should have rodent and termite resistance

The quality, safety, and profitability of a solar plant depend on the workmanship and the efficiency of its components.

Nitesh Vaghasiya (Chairman & Managing Director) ULTRACAB commented, “While selecting a Solar Cable for Project, the quality of solar cable played a vital role. A quality Solar Cable having three mainline properties:

- Conductor: Highest Conductivity with corrosion protection of conductor should be required for quality solar cables, for the same We are using 99.97% pure EC grade copper with tinned plating for protection against moisture and weather effect.

- Insulation: High Insulation resistance properties should be required of Insulation, which we achieve by using high-quality cross-linked material.

- Sheathing: UV and Weather Resistivity of Sheathing material should be required which we achieve by using high-quality UV and weatherproof plastic materials.

Choosing the right wire for your solar energy system is critical to project functioning properly and remaining undamaged. Therefore, ensuring the best quality standards is a must for the system, which has a life of over 25 years.

V K Bajaj of Apar Industries pointed out, “Solar plants are installed for an estimated life of over 25 – 30 years which can be assured only if Cross-Linking is done by the Electron Beam irradiation process. High Electrolytic grade of Copper or 8000 series Aluminium can assure long-term cable performance. Cables rated 105 Deg C duty, and Rodent/Termite resistant features will ensure the long life of Cables.

To keep up with changing installation practices and to bring the best product in the market, solar cable manufacturers have continuously taking up the task of matching costs with long-term efficiency, as well as keeping an eye on continuous product innovations.

In a Nutshell – Importance of solar cables quality

The efficiency, reliability, and profitability of a solar plant is determined by the quality of its components. It’s important to pick the correct wire for your solar energy system if you want it to work properly and stay intact. Since solar PV systems have a lifespan of more than 25 years, sourcing solar cables from licensed and accredited manufacturers are critical to ensuring quality and safety.

Naman Singhal- Director, PRIME CAB commented that one should understand that cable constitutes a very small share in terms of its value in a solar project and at the same time plays a very crucial role in its overall efficiency and stability in the long run. So, compromising in its quality for cost-cutting would not be a wise decision in my opinion.

Since cables are the lifeline of a solar electric network, proper wire and cable selection are critical in the long run, as low-quality cables result in higher maintenance costs.

In a nutshell, if you keep the above-given considerations in mind, as well as the underlying safety measures, you will be able to find and source the best quality solar cables for your photovoltaic project.

Leading Solar Cable Manufacturers in India

APAR Industries Limited :

APAR Industries Ltd, an Rs 8000 Cr company, is a leading and the largest & widest range of cables for Renewable energy in India. The product range includes HT/LT XLPE Power & Control cables, Elastomeric & Ebeam Irradiated cables, Fiber optic cables. The company has installed 1.5/2.5/3.0 MeV Ebeam machines and uses Electron Beam Irradiation technology for cross-linking of Solar DC cables and also offers 105 Deg C operating Temp cables in HT & LT Power Cables.

Birla Unistar

Vindhya Telelinks Ltd. (VTL) belongs to the prestigious MP Birla group enjoying an excellent market reputation due to its superior product quality and support to its customers. The group has been pioneering in the field of power and telecommunication cable industry. VTL has earned an enviable reputation and leadership position in the market and has a satisfied customer base in the domestic market as well as overseas market.

Finolex

Finolex Cables Ltd is an Indian manufacturer of electrical and telecommunication cables based in Pune, Maharashtra. It is the flagship company of the Finolex Group, established in 1958. Its manufacturing plants are located in Pune, Goa, and Roorkee.

HPL

HPL is a well-established brand having more than four decades of manufacturing experience of wide range of electrical products including Wires & Cables. The company operates through seven manufacturing units and two R&D centers along with more than 900 dealers and distributors, and over 27,000 retailers.

Havells

Havells is a leading power distribution equipment manufacturer in India. The company provides a wide spectrum of products, including Cables & Wires. It operates through a large network of more than 7900 dealers, 12 manufacturing plants, and 40 branches in India and exports to 40 other countries.

KEI

KEI’s products encompass low, high and extra-high voltage cables. KEI has strategically located manufacturing facilities in Bhiwadi, Chopanki, Silvassa, Pathredi. It also has robust R&D capabilities. The company also has a global presence.

Lapp

LAPP Group is a leading supplier of integrated solutions and branded products in the field of cable and connection technology. LAPP is a German company providing a wide range of cables, industrial connectors, accessories, and engineered solutions. It operates through 18 production sites and over 40 sales companies worldwide.

Prime Cable

Prime Cable Industries Pvt. Ltd. is a renowned name in manufacturing power, communication and solar cables having valuable experience of over two decades. Accredited with ISO 9001: 2015 – all company’s products are also certified with various national and international standards. Company’s manufacturing unit is equipped with all modern machine and laboratory equipment. Its vast product catalogue includes aerial-bunch cables, control and instrumentation cables, power cables, high tension power cables, low tension power cables, thermocouple extension and compensating cables, battery cables, and solar cables.

Polycab:

Polycab is engaged in manufacturing and selling of wires and cables and has 25 manufacturing facilities, along with an extensive supply chain network which helps its products to reach across India.

RR Kabel

RR Kabel is one of the leading companies in the electrical industry in India. The Company has 27 product licenses as well as three manufacturing certifications. Its products are also sold in more than 80 countries across the world.

ULTRACAB (INDIA)

Ultracab (India) Limited is an ISO 9001: 2015 certified company – incorporated in the year 2007 and is engaged in the manufacture and export of wires and cables. Ultracab is ISO 9001-2015, ISO 45001 and OHSAS 18001 certified company, and our products are certified with ISI: 694, ISI: 1554, ISI: 7098, ISI: 14255, CE, UL (USA), cUL (Canada), TUV and also qualities are tested and approved by ERDA and CPRI. Ultracab manufacture solar cables with different sizes starting from 0.5 sq.mm up to 240 sq.mm. (As per EN (European) and BIS (Indian) Standards).